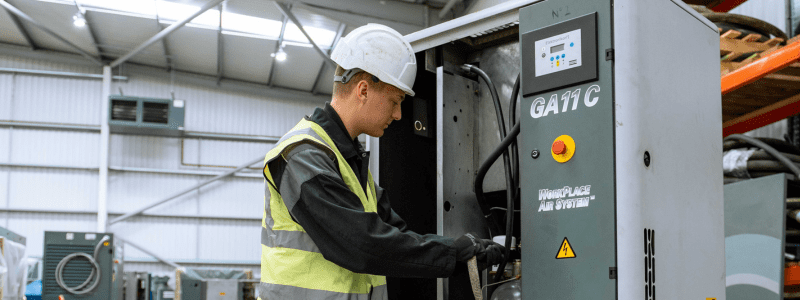

At PPS, we know air compressors inside out. Keeping your business running and your machinery performing at optimum levels is important to us. We offer UK-wide air compressor servicing, maintenance and repairs, along with a range of service agreements and packages.

Our aim is to work with you to understand your production, so we can provide the right solution and appropriate level of aftercare to ensure your compressor continues operating at peak performance throughout its working life.

Our factory trained, qualified engineers can provide maintenance, repair and overhaul for air compressors and ancillary equipment, including:

Our company and our refrigeration engineers are REFCOM certified under the current F-Gas legislations. Current hazardous waste regulations are fully adhered to and we hold a ‘Hazardous Waste Transfer’ certificate (please contact us if you require a copy for your records).

Why take unnecessary risks with your compressed air supply when there are experts at hand to keep your compressor in tip-top condition and reduce the risk of downtime.

Our service and maintenance support is designed to give you peace of mind. We can track, monitor and maintain your systems so you can focus on getting your job done.

Our range of tailored service contracts take into account the nature of your business and how critical a reliable continuous supply of compressed air is for your production requirements. Browse the types of cover available or get in touch to discuss with our team.

Covers both routine maintenance and unexpected failures, and is available on new Atlas Copco air compressors within 12 months of the commissioning date.

Length = 5, 7, 9 or 10 years.

Delivers complete peace of mind for any brand of air compressor with both routine maintenance and unexpected failures covered.

Length = 5 or 7 years.

Covers only the routine maintenance of any brand of air compressor, but protects you from price rises for the full term of the plan.

Length = 1, 3 or 5 years.

A one year agreement for the routine maintenance of any brand of air compressor.

Length = 12 months only.

For full details of the available plans, contact us.

Our genuine 24/7 emergency call out service is available to all. Whether you are a new or existing customer, and whatever brand of compressor you use.

Technical expertise is our strength, which means that we can troubleshoot problems and get your machinery back up and running as quickly as possible. We can also make recommendations to help reduce the likelihood of future breakdowns and offer hire air compressors and other equipment if longer term repairs are required.

Service and maintenance contracts have kept Cirteq’s machines running and reliable for many decades, including their oldest compressor, installed over 45 years ago.

Service and maintenance contracts have kept Cirteq’s machines running and reliable for many decades, including their oldest compressor, installed over 45 years ago.

“PPS are a great team to work with. I have peace of mind and working with them takes something off my plate. They leave me knowing it’s left in good hands and that I know I don’t have to worry about the compressors or the plant room.

“Without the compressors we wouldn’t run, so working with a company that gives me no headaches is all you want.”

Bob Holinski, Facilities & Engineering Manager, Cirteq Ltd